Polishing equipment is essential in achieving a smooth and polished surface finish for various materials. Whether it’s for aesthetic or functional purposes, choosing the right polishing equipment for your application is critical in achieving the desired results.

Material Type

One of the most critical factors to consider when choosing polishing equipment is the type of material you are working with. Different materials require different types of polishing equipment and techniques. For instance, metal materials require different polishing machine compared to plastic or ceramic materials. Therefore, it’s important to select polishing equipment that is designed to work with the specific material you are working with to achieve the best results.

Surface Finish Requirements

The surface finish required for your application is another crucial factor to consider when choosing polishing equipment. Some applications require a mirror-like finish, while others require a matte finish. The type of polishing equipment you choose should be capable of achieving the required surface finish. Some polishing equipment is designed to achieve a specific type of finish, while others can be adjusted to achieve different types of finishes.

Production Volume

The volume of production is another factor to consider when choosing polishing equipment. For low-volume production, manual polishing machine such as hand-held polishing machines may be sufficient. However, for high-volume production, automated polishing machine may be more efficient and cost-effective. Automatedcan handle large volumes of materials, ensuring consistent and repeatable results, reducing labor costs, and increasing production efficiency.

Cost

The cost of polishing equipment is another factor to consider when choosing the right equipment for your application. The cost of polishing equipment varies depending on the type of equipment, brand, and features. It’s important to choose equipment that fits within your budget while still delivering the required level of precision and quality.

Brand Reputation

In conclusion, choosing the right polishing machine for your application is critical in achieving the desired level of precision and quality. Factors to consider when choosing polishing equipment include material type, surface finish requirements, production volume, cost, and brand reputation. It’s important to select equipment that fits within your budget while still delivering the required level of precision and quality.

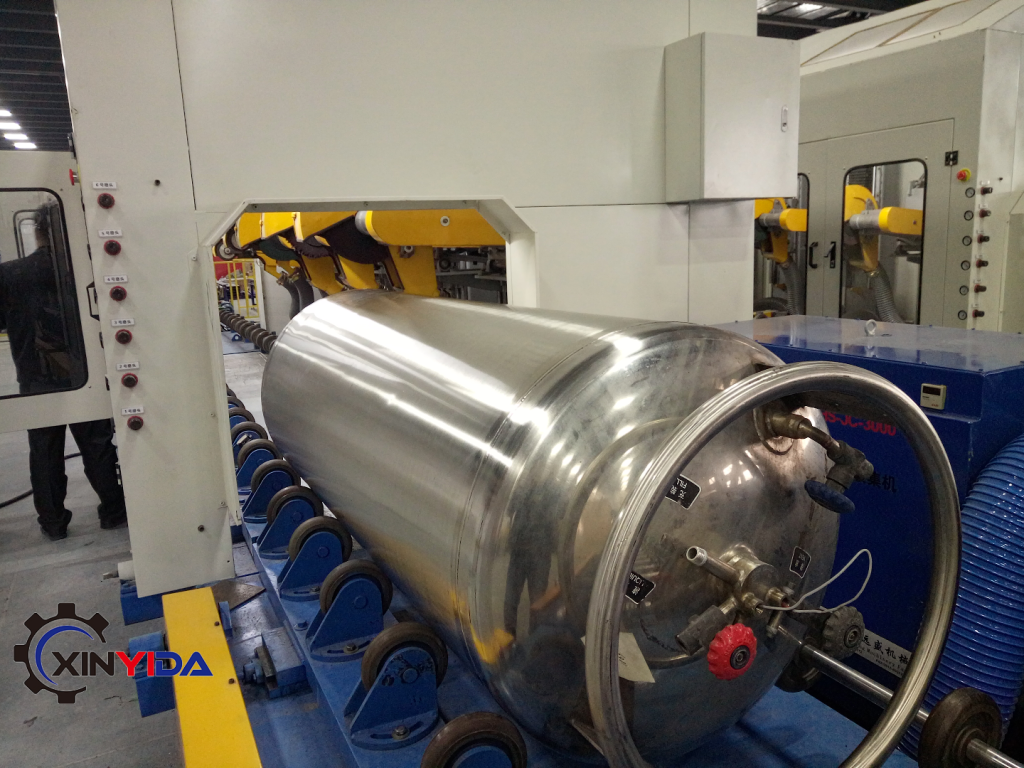

Xinyida is a reputable brand that specializes in the manufacture of high-quality polishing equipment. Their equipment is designed to work with different types of materials, achieving a variety of surface finishes, and handling different production volumes. Xinyida’s equipment is also reliable, efficient, and durable, ensuring that you get consistent and repeatable results.